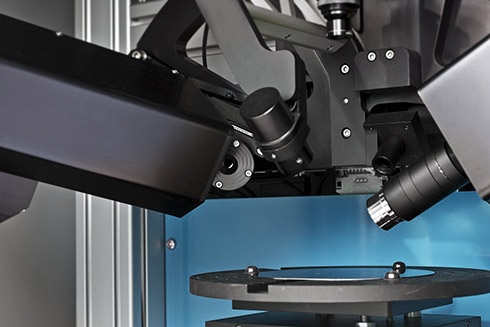

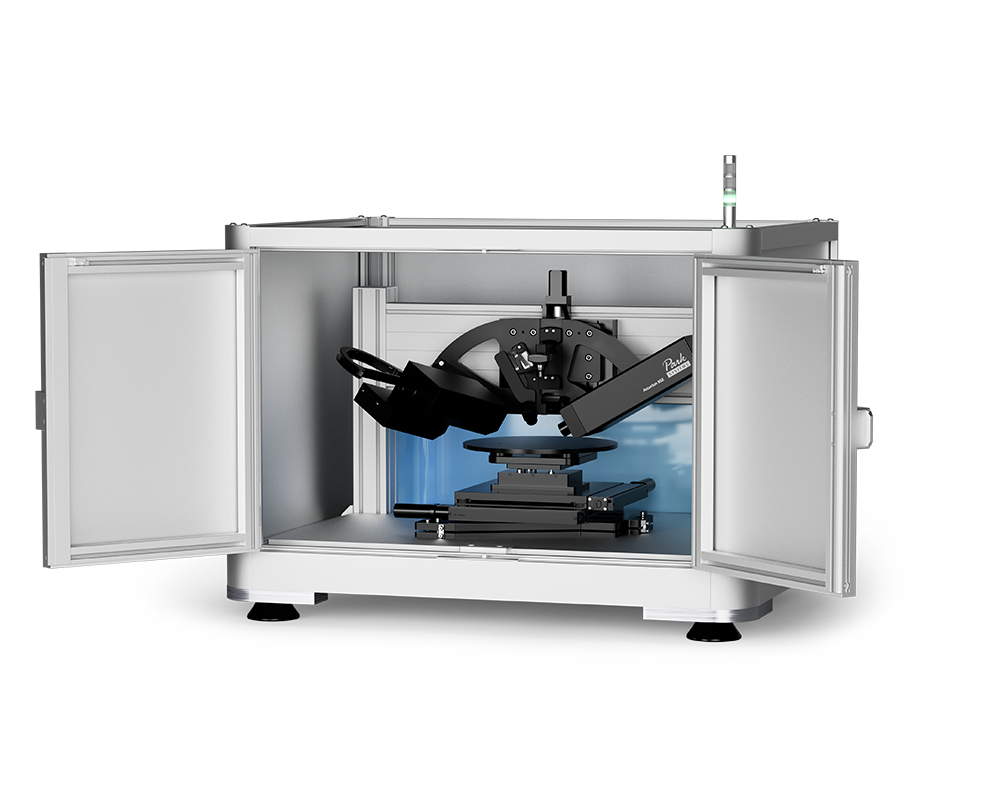

Accurion RSE

Referenced Spectroscopic Ellipsometry Fast Inspection of Thin Films and Surfaces

The Referenced Spectroscopic Ellipsometer (RSE) is an ellipsometer based reflectometer, designed for high speed thickness mapping in, e.g., quality control. It allows to accurately measure thicknesses from 0.1 nm - 10 µm. With 200 complete spectra recorded per second, a 100 mm x 100 mm area can be investigated in only 12 minutes while acquiring 67000 spectra.